01 Overview

The wheel hub bearing testing machine is specially used for testing the fatigue life of wheel hub

bearings of light and heavy-duty vehicles and trains, and provides test conditions for evaluat

ing the performance of wheel hub bearings. Simulating the loading & motion state of the hub

bearing under driving state, and the real-time data are collected by the temperature, vibration,

speed and other sensors for data analysis to determine the bearing failure. The control system

can automatically collect, process, display, print data and test results, with alarm and limit

protection functions. 04 Specifications and main parameters Mode Parameter Max radial force (KN) Max axial force (KN) Max speed (R / min) Distance between radial loading axis and hub bearing edge (mm)

Distance between axial loading axis

02 Working principle

03 Product Characteristics

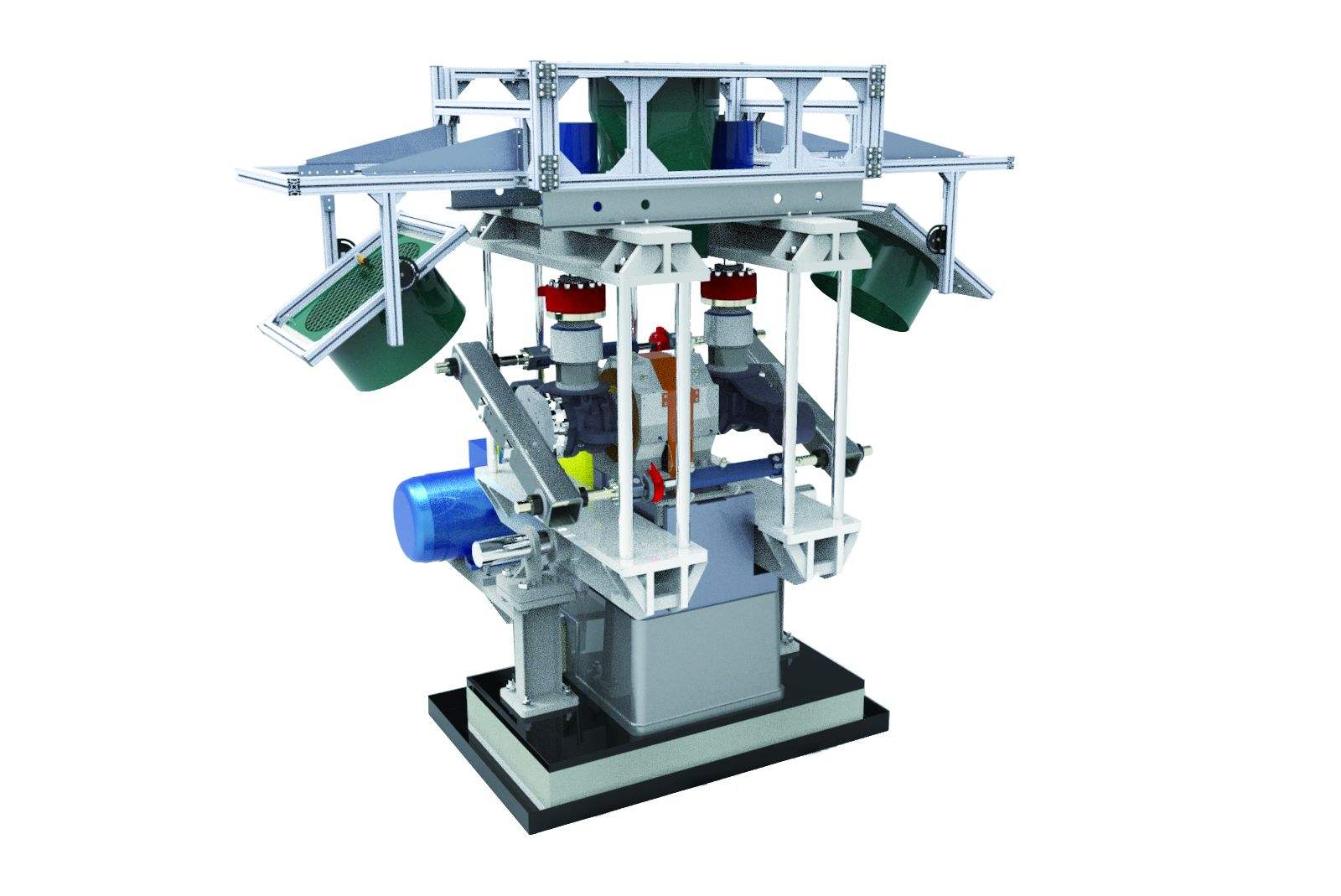

Automobile hub bearing test bed

Theautomobile hub bearing test bed can realize radial loading of two groups of hub bearings and simulate the load of vehicle loading on the hub bearing. Two sets of hub bearings are loaded axially at the same time, and the distance between loading axis and hub bearing axis is

adjustable, which is used to simulate the axial load on the hub bearing exerted by the ground through the tire in the turning process. At the same time, the outer ring of the hub bearing is driven by a variable frequency motor to realize the omnidirectional simulation of the rotation of the bearing to simulate the load and motion of the hub bearing.

Railway hub bearing test bed

The railway hub bearing testbed can realize the radial and axial loading of two groups of railway R3 bearings. At the same time as the load bearing, the inner ring of the bearing is driven by the variable frequency motor to simulate the rotation of the bearing. And through the fan to carry out strong wind cooling on the bearing, simulate the air volume and wind speed under driving condition. It can fully stimulate the load and motion state of the bearing.- Sensors of temperature, vibration, and rotation rate collect real-time data for data analysis to determine the bearing failure. The control system can automaticallycollect, process, display and print data and test results, and it has alarm and limit protection functions.

04 Specification and main parameters