01 Purpose and function

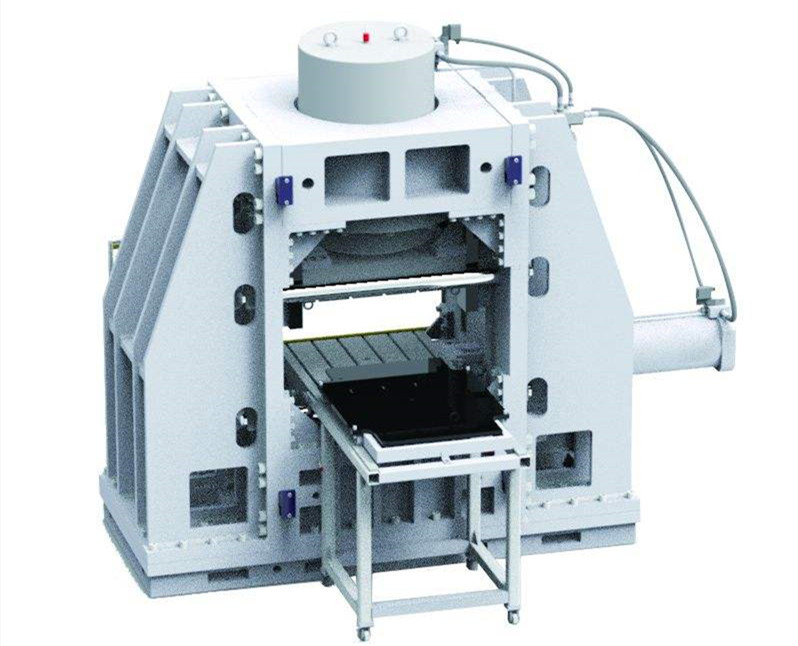

Rubber bearing compression shear testing machine is mainly used for conventional basin rubber bearings, spherical steel bearings, building vibration isolation rubber bearings, etc. Compression resistance elastic

modulus test, shear elastic modulus test, shear bonding performance test, shear aging test, friction coeffiffifficient test, and test of axial compression deformation and radial deformation under loading test of highway bridge basin rubber bearing. It can be carried out for dynamic tests such as basin rubber bearings, spherical steel bearings, building vibration isolation rubber bearings horizontal equivalent rigidity, equivalent damping ratio. It can also conduct the compression resistance strength test of other metal or non-metal materials

Rubber bearings

Part 1: Test Method for Vibration Isolation Rubber Bearings GB 20688.2-2006

Part 2: Bridge Vibration Isolation Rubber Bearings GB 20688.3-2006

Part 3: Building Vibration Isolation Rubber Bearings GB 20688.4-2007

Part 4: General Rubber Bearings TB ∕ T 1893-2006

Railway Bridge Plate Rubber Bearing TBT 1893-2006

Railway Bridge Plate Rubber Bearing, etc.

02 Product Characteristics

The parts in contact with the rolling guide block are all quenched bearing steel plates to fully ensure the strength and wear resistance.

The host of this product adopts a high rigidity load frame, an upper hydraulic cylinder, a full-stroke guiding structure, a direct drive valve and a measurement control system, which has strong anti-pollution ability and a wide and stable control range

The pressure table is connected below the vertical oil cylinder, and the pressure table is pushed by the oil cylinder to press the test piece. The rolling guide rail block is installed on the side of the pressure table, guided along the column, and bears the lateral shearing force. The rolling guide rail block is fifixed under the sliding platen to reduce the friction with the lower beam.

03 Specification and main parameters